End-to-End Electronics Manufacturing services: From Design to Delivery

Our comprehensive services span the entire product lifecycle - from product design consultation through final assembly and support. Built on technical expertise and precision, we excel in both high mix low volume and volume manufacturing, offering specialized printed circuit board assembly (PCBA), surface mount technology (SMT), through hole technology (THT) and testing services for superior electronic products and solutions. As a leading EMS company and trusted EMS partner, we deliver advanced solutions across the electronics value chain for various industries.

Core technical expertise: Building advanced electronic Solutions across the value chain.

From PCB, hardware and software design to manufacturing and testing, our expert teams and skilled engineers deliver integrated solutions that improve performance and reliability while reducing costs. We collaborate closely with customers to meet specific requirements and adapt our processes to handle evolving industry demands in the electronics manufacturing industry.

Our Electronics Manufacturing Services design team excels in PCB layout, hardware development, software. As a full-service manufacturer, we transform concepts into manufacturable electronic products through integrated development processes and functional prototyping that validates designs before production engineering begins.

We optimize designs using Design for Manufacturing and Assembly (DFMA) and design for test (DFT) methodologies while establishing robust electronics manufacturing processes. The scope of our services includes industrialization, prototyping and project management before serial production. Our quality control systems and process optimization ensure consistent excellence across all printed circuit board assemblies and electronic assemblies – meeting the highest quality standards and regulatory requirements.

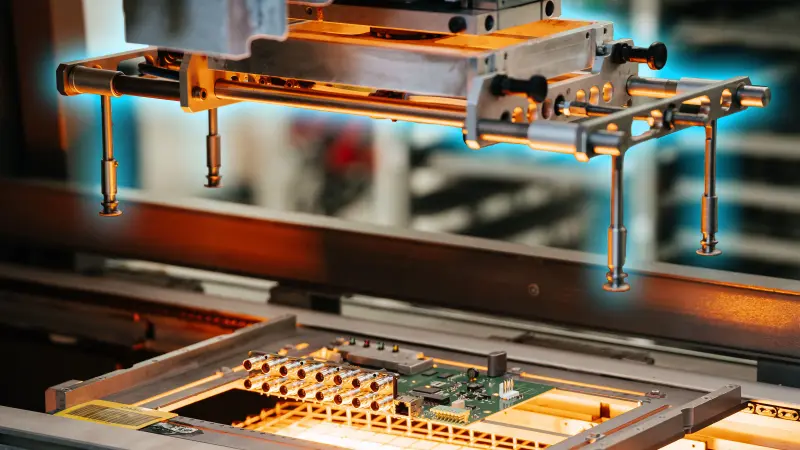

Using advanced surface mount technology (SMT) and through-hole technology (THT), we deliver precise PCB assembly services for all production volumes. Our Electronics Manufacturing Services capabilities includes final assembly with advanced automation and robotization adapted to the product and volume needs, as well as testing services and specialized processes that meet the highest industry standards.

Our component supply team secures electronic components globally while managing vendor relationships for reliable delivery. We implement supply chain solutions that mitigate risks and enhance the stability of our global supply chain.

We leverage our global footprint with our deep industry knowledge and extensive experience in advanced Electronics Manufacturing. Our diverse range of services supports multiple industries with exceptional quality, backed by our responsive, innovative team that puts customers first.